5 Things That Set Expert Micro Injection Molding Companies Apart

When parts need to be incredibly small yet extremely precise, manufacturers often turn to micro injection molding. This specialized process allows for the production of rubber components with dimensions that can be measured in fractions of a millimeter. Because of the complexity involved, not all micro injection molding companies are equipped to handle these projects. Below, you’ll find tips on what to look for in a micro injection molding company so you can get the best results possible.

High-Precision Mold Design and Fabrication

Micro molds must be built to create extremely tight tolerances. This requires advanced tooling and careful design considerations. Expert molders invest heavily in precision moldmaking and typically have in-house capabilities to ensure ongoing accuracy.

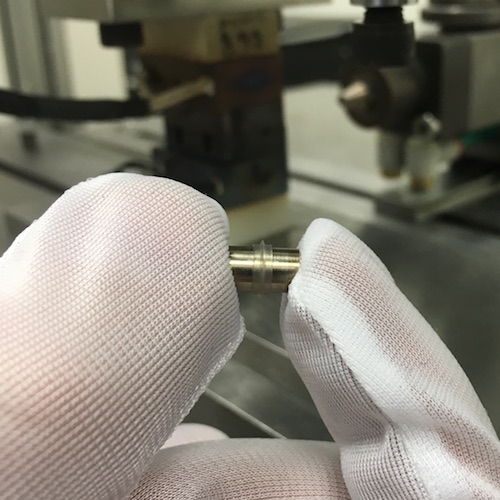

Specialized Equipment

Standard molding machines aren’t always suitable for producing micro parts. Instead, leading micro injection molding companies use equipment designed for extremely small shot sizes. These machines allow for tight control over temperature, pressure, and material flow. As a result, you get consistent results and reduce the risk of defects.

Cleanroom or Controlled-Environment Production

Contamination is top of mind in industries like medical technology and electronics. Top micro molders operate cleanrooms or tightly controlled environments to maintain part integrity. This level of control ensures parts meet regulatory requirements.

Rigorous Quality Control

Your chosen micro molding partner should have advanced inspection methods to verify performance. The best micro injection molding companies have quality control built into every stage of production.

Deep Knowledge of Material Qualification and Testing

Choosing the right rubber compounds is important for the part’s efficacy. Experienced molders help customers navigate options based on properties like chemical resistance, durability, and flexibility. They can test and qualify materials to ensure the chosen compound is the best fit for the application.

Work with Moldtech for Your Rubber Molding Needs

Searching for micro injection molding companies? Moldtech has been offering high-quality rubber injection molding services for decades. Located in Lancaster, NY, we are a vertically integrated manufacturer with close to 50,000 square feet of production space. This includes clean room and climate-controlled workspaces.

We’re constantly evolving our capabilities, which allows us to reduce risk, improve consistency, and drive down total costs. Our parts are trusted by some of the biggest companies in the world. We’re proud to support customers like Boeing, Bosch, Johnson & Johnson, the U.S. military, and more. With engineering know-how, hands-on problem-solving, and a relentless drive to get it right, we’re ready to take on your next project. Contact us today for a quote.