Micro Molding

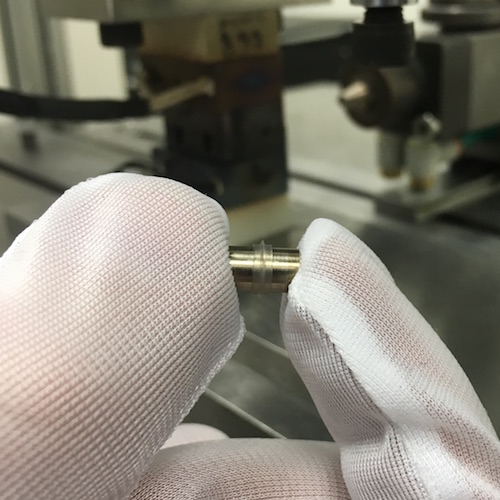

Are you in need of extremely small, detailed components with tight tolerances? Our accurate micro molding capabilities are ideal for medical, aerospace, and electronics applications. This specialized process is used to manufacture extremely small components with tight tolerances and intricate geometries. These parts often weigh less than a gram and require advanced processes to ensure accuracy. Learn more about why companies trust us for their micro molding needs below, or reach out to our team for a quote.

Why Trust Us for Micro Molding Processes?

Over the last few decades, Moldtech has become a well-known name in the industry. Using advanced technology and state-of-the-art processes, we solve complex engineering challenges and are a go-to partner for critical applications. When you need a partner that delivers quality results, turn to us.

Located in Lancaster, NY, our nearly 50,000 square feet of vertically integrated production space is capable of managing every step of the manufacturing process. We’ll handle everything from the initial design to the final arrival at your facility. This means you get unmatched control over the entire process. Moreover, you eliminate the need for multiple suppliers, which reduces complexity in the supply chain.

Our team operates 24 hours a day, five days a week, allowing us to quickly respond to immediate requests. Whether you’re looking for a single prototype or a large run, we can help. And, if your project needs extra safeguards, we offer clean rooms and climate-controlled environments.

Backed by decades of experience and the resources of Newbury Franklin Industrials, we’re ready to take on your next project. In fact, we’re trusted by organizations like Boeing, Bosch, Johnson & Johnson, and the U.S. military. If you need high-quality parts that stand up to tough environments, contact us today.

Get a Quote from Our Team

Ready to learn more about what we can do for you? Our team is ready to get the details of your project and create a quote. Contact us today to get started.