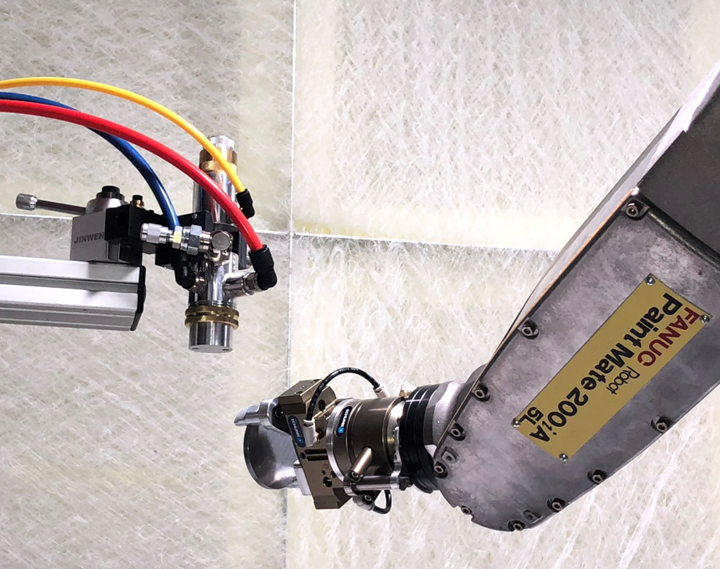

Coating Application (HNBR, FKM)

Our high-performance elastomeric coating application applies a thin layer of elastomer to rubber parts on optimal materials. This gives the part better strength and isolation characteristics, provides for additional chemical and environmental resistance, and increases the temperature capability of the base material.

Our team is well-versed in HNBR and FKM elastomeric coating procedures. Hydrogenated nitrile rubber (HNBR) can meet higher temperatures than standard NBR while retaining resistance to mineral-based oils. It’s also a great choice for parts that need to resist glycol-based coolants, hot water, and ozone. FKM is a copolymer made of highly fluorinated hydrocarbons with great resistance to media, ozone, and aging. The material is also stable in fuels and petroleum-based oils and greases.

Learn why so many companies trust Moldtech for elastomeric coating below, or reach out to our team for a quote.

Why Choose Moldtech?

For over three decades, Moldtech has been the rubber molding partner of choice for some of the biggest companies in the world. Boeing, Bosch, Johnson & Johnson, and the U.S. military all trust us for their most critical components.

As a vertically integrated manufacturer, we’re able to handle all aspects of the project from start to finish. This reduces complexity, as you don’t have to manage multiple vendors. Additionally, you’ll retain full control over your products.

Our facility has nearly 50,000 square feet of production space, including clean rooms and climate-controlled workspaces. We operate five days a week, 24 hours a day. With this robust schedule, we stand ready to take on advanced challenges.

Get a Quote Today

Ready to learn more about what we can do for you? Contact our team for a quote.