How to Shape Silicone Rubber Through Injection Molding

Silicone rubber has become a staple material in modern manufacturing, thanks to its ability to withstand extreme conditions while maintaining flexibility and durability. From aerospace seals that face rapid temperature shifts to medical components that require both precision and safety, silicone has proven to be one of the most versatile materials available. But while silicone rubber itself is widely known, the methods used to shape and process it have continued to evolve. One of the biggest changes has been the growing use of injection molding, which allows manufacturers to create high-quality parts more quickly and with greater design freedom than ever before. Below, we’re diving into how to shape silicone rubber so your business can reap the benefits.

Understanding Silicone Rubber

High-consistency rubber (HCR) has dominated manufacturing processes for years. The material can be used at temperatures ranging from -50℃ to +300℃, making it a great option for demanding industries. Additionally, these elastomers have great aging resistance. As a result, HCR has been used in industries like aerospace, automotive, healthcare, and more.

However, liquid silicone rubber (LSR) has replaced HCR in many areas. LSRs have a lower viscosity, meaning they flow more easily. This makes LSRs more readily processable via injection molding. Conversely, HCRs have a higher viscosity, meaning they have to be processed through more labor-intensive methods like transfer and compression molding. As a result, LSRs have become more popular.

How to Shape Silicone Rubber with Injection Molding

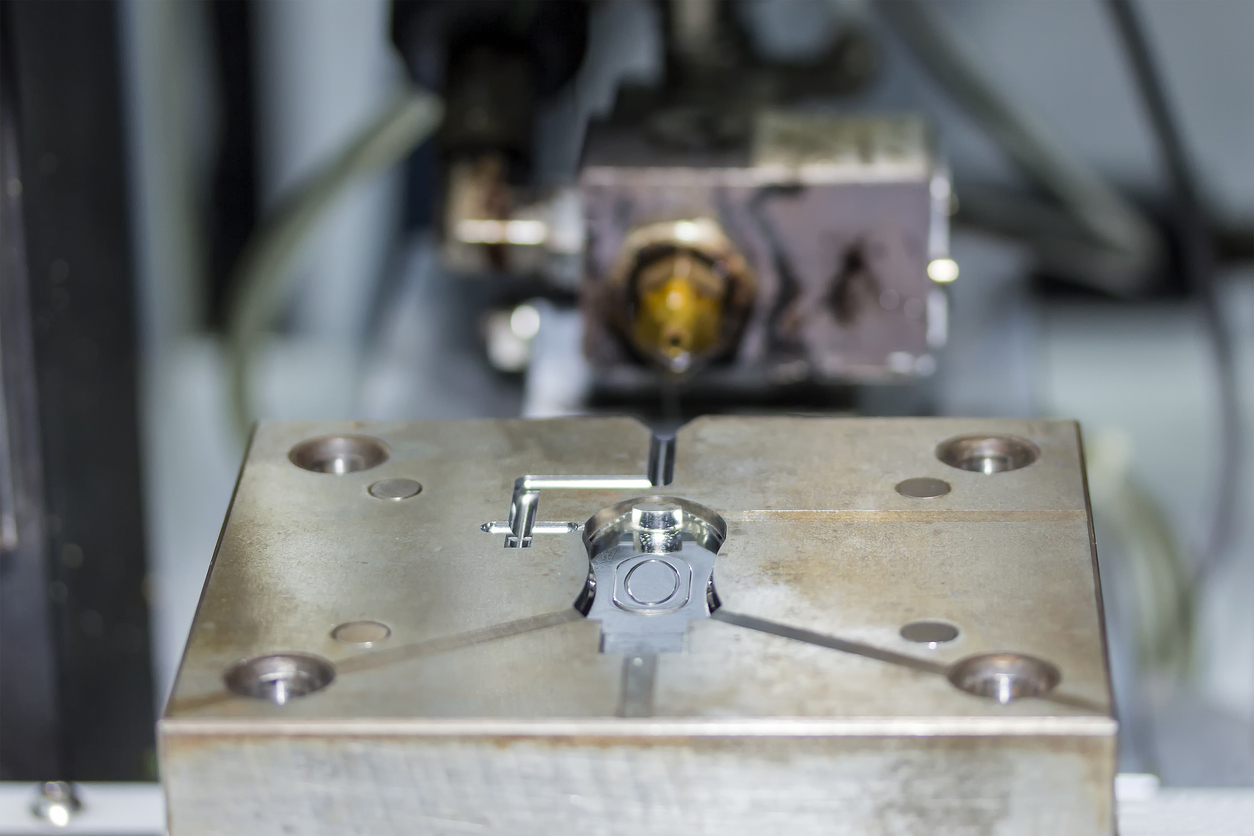

Before we get into the advantages of rubber injection molding, let’s discuss how the process works. The method starts by mixing two materials together within the injection molding machine — usually liquid silicone rubber mixed with a curing agent. From there, the material enters the barrel of the press. Inside the machine, a ram moves forward, pushing the chilled silicone rubber into a warm mold. The mold then opens, and the part can be manually removed.

The process is simple and is usually more cost-effective than other manufacturing methods for large runs. That’s why it’s becoming more popular in a range of industries.

Advantages of Silicone Injection Molding

Not sure if molding silicone through injection molding is right for you? Here are the benefits you can expect to receive:

High Repeatability for Large Production Runs

As mentioned above, liquid silicone molding uses a specialized mold to form the final part. With this mold, it’s easy to ensure high repeatability, even for large production runs. This is especially valuable for high-volume applications in medical, automotive, and consumer goods. It minimizes human error and reduces the need for rework and inspection.

Complex Geometries with Minimal Waste

Silicone’s flow characteristics allow it to fill intricate mold designs. As a result, it’s easier to produce parts with undercuts, thin walls, and fine details that might not be possible with other manufacturing processes. And, the injection molding process is highly efficient, using just the right amount of material. This leads to very little scrap compared to other manufacturing processes.

Excellent Part Quality and Surface Finish

Silicone injection molding produces parts with smooth surfaces and tight tolerances straight out of the mold. This reduces or eliminates secondary finishing processes. That means you get high-quality components that are both functional and aesthetically pleasing.

Still Wondering About How to Shape Silicone Rubber? Moldtech Has the Answers

For decades, Moldtech has been focusing on rubber injection molding for complex, highly engineered parts. If you’re still wondering about how to shape silicone rubber, contact us. Whether you’re developing a new product or need to scale quickly, we’re here to make the process smoother.

Located in Lancaster, NY, we’re a vertically integrated manufacturer with close to 50,000 square feet of production space. This includes clean room and climate-controlled workspaces. We design, manufacture, and assemble your part in-house, giving you maximum control over the process. We offer a range of products, from seals and gaskets to dampers and isolators, and more.

Our parts are trusted by some of the biggest companies in the world. In fact, we’re proud to support customers like Boeing, Bosch, Johnson & Johnson, the U.S. military, and more. When you need parts you know you can rely on, trust us.