Quality Assurance in Rubber Molding: How to Prevent Defects

Defective rubber products can be very costly, especially in industries like the automotive, medical, and consumer markets. Common issues with rubber molding include defects, inconsistent quality, material waste, and production delays. Luckily, comprehensive quality assurance processes can prevent defects and ensure reliable performance. Let’s take a closer look at the importance of the quality assurance process and how Moldtech guarantees enhanced reliability for every project.

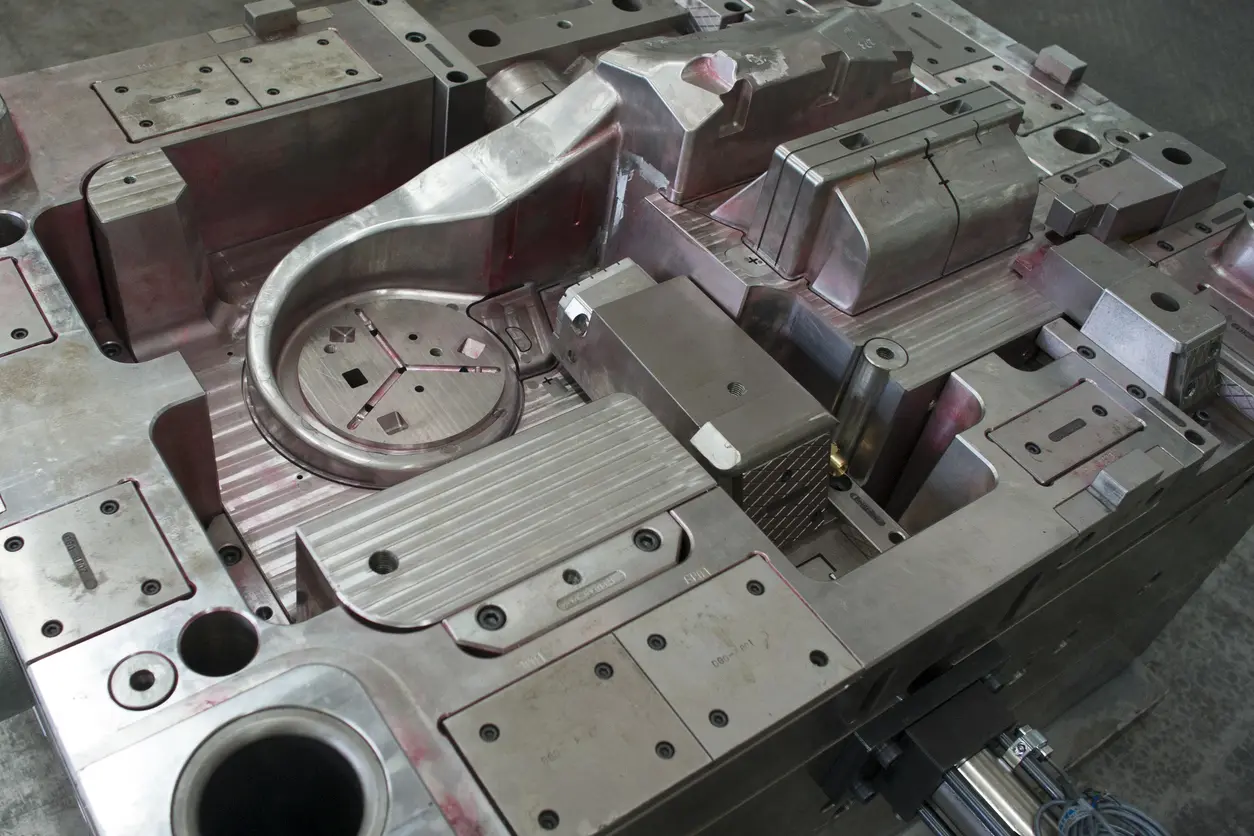

Understanding Rubber Molding and Its Challenges

In the rubber molding process, precision is critical. Common rubber molding defects can severely impact part performance, and include surface defects like bubbles and blisters. There is also the risk of dimensional defects like shrinkage or warping, and mechanical defects like weak spots or incomplete curing.

The causes of these defects are varied, and can include improper mold design or maintenance, or incorrect material handling. Inconsistent temperature or pressure, as well as human error, can result in defects that impact performance and quality.

The Role of Quality Assurance in Rubber Molding

Quality assurance is a proactive solution rather than a reactive fix, and in rubber molding, quality assurance is particularly important. It is a systematic approach to prevent defects. Key QA processes include material inspection and verification, as well as mold design validation. It’s also critical to process monitor for temperature, pressure, and more. With in-line inspections during production and final product testing for hardness and dimensional accuracy, the quality assurance process is crucial for ensuring performance.

A comprehensive QA system can reduce material waste and costs, and improve both product reliability and lifespan. It minimizes downtime and rework, while also enhancing customer satisfaction and brand reputation.

Best Practices for Preventing Rubber Molding Defects

Preventing molding defects takes time and careful consideration. Material management is key, so that means using high-quality raw materials and proper storage to prevent both contamination and degradation. Mold design and maintenance must also be carefully considered. Invest in precision mold engineering, as well as regular cleaning, inspection, and mold monitoring to enhance accuracy.

Ensure you have proper process controls in place to maintain consistent temperature and pressure. Implement process automation whenever possible to reduce defects. A skilled workforce is also key. It’s important to train operators on defect detection and process adherence, and encourage communication between production members and QA teams. Testing and inspection are also important processes that cannot be skipped. This includes visual inspection, dimensional checks, and hardness testing, as well as other advanced techniques to identify internal defects.

How Moldtech Ensures High-Quality Rubber Molding

Moldtech provides solutions, and we have specialized knowledge in preventing common rubber molding defects. Our components are trusted by some of the biggest companies in the world, including Boeing, Bosch, Johnson & Johnson, the U.S. military, and more. We use state-of-the-art facilities and comprehensive QA processes to provide extensive customer support and an unmatched collaborative approach, from design to final product.

Rubber molding defects are costly but preventable, and tailored QA solutions from an expert manufacturer can help. Contact Moldtech today to get started.