How to Ensure Rubber Parts for Electronics Are Built to Last

Electronics are only as reliable as the components that protect them. Rubber parts quietly provide the sealing, insulation, and protection that keep sensitive systems functioning. Poorly made components can compromise the performance of the entire device. That’s why manufacturers who build electronics must take a careful, systematic approach to designing and sourcing rubber parts for electronics. Below, we’re outlining how to ensure your components are built to last.

Understand the Application Requirements

The first step is understanding the demands of the application. Every environment places unique stresses on a component. That could mean exposure to extreme temperatures, persistent humidity, corrosive chemicals, or even prolonged sunlight. These stressors can cause significant wear and tear, meaning you must select the right materials that can stand up to the application. Additionally, it’s important to consider mechanical requirements like flexibility, tear resistance, vibration absorption, and compression.

Choose the Right Rubber Material

As mentioned above, your application requirements will determine which materials are suitable for your parts. The type of rubber you choose will determine how well a part resists heat and cold, how it performs as an insulator, and how it withstands chemicals or long-term wear. Partnering with a manufacturer who has the expertise to recommend and source the right compound ensures that the material aligns with the performance needs of the electronics it protects.

Precision in Design and Engineering

After you’ve determined the material, the design and engineering phase comes next. Your manufacturing partner should create a prototype that helps confirm the part will fit properly and work as intended. A well-thought-out design minimizes weak points that could lead to premature wear or failure, while also building in the features needed for long-term performance.

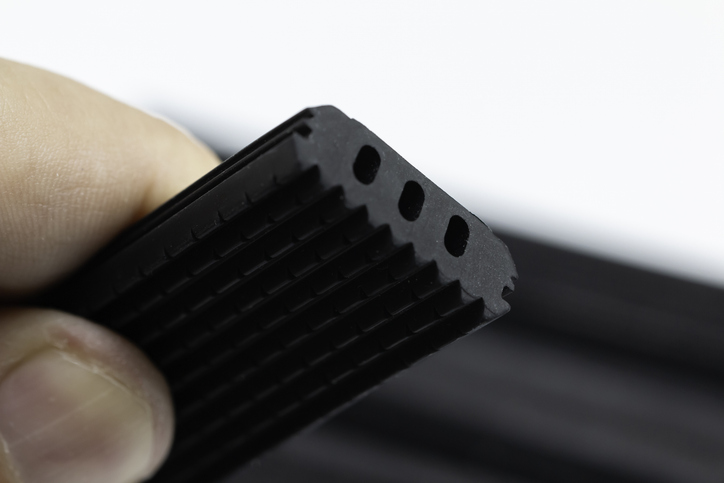

Advanced Manufacturing Processes

The manufacturing process will also play a role in the final outcome. Even the best design will fall short if the production method is subpar. Modern rubber molding techniques, such as injection molding, allow manufacturers to create parts with complex geometries and tight tolerances. These methods reduce material waste and ensure consistent results from one production run to the next. When a supplier invests in the right manufacturing technology, they can produce rubber parts that perform exactly as engineered, batch after batch.

Testing and Quality Assurance

No part should leave the factory without thorough testing. Rubber components for electronics must undergo checks to confirm that they meet specifications. A strong testing and quality assurance program ensures components are meeting the highest standards when they reach your assembly line. As a result, you’re strengthening your product’s performance and your reputation.

Partner with an Experienced Manufacturer

For decades, Moldtech has been focusing on rubber injection molding for complex, highly engineered parts. Located in Lancaster, NY, we’re a vertically integrated manufacturer with close to 50,000 square feet of production space. We design, manufacture, and assemble your part in-house, giving you maximum control over the process. We offer a wide range of products, from seals and gaskets to dampers and isolators.

Our parts are trusted by some of the biggest companies in the world. In fact, we’re proud to support customers like Boeing, Bosch, Johnson & Johnson, the U.S. military, and more. When you need parts you know you can rely on, trust us. Contact us today to get started.