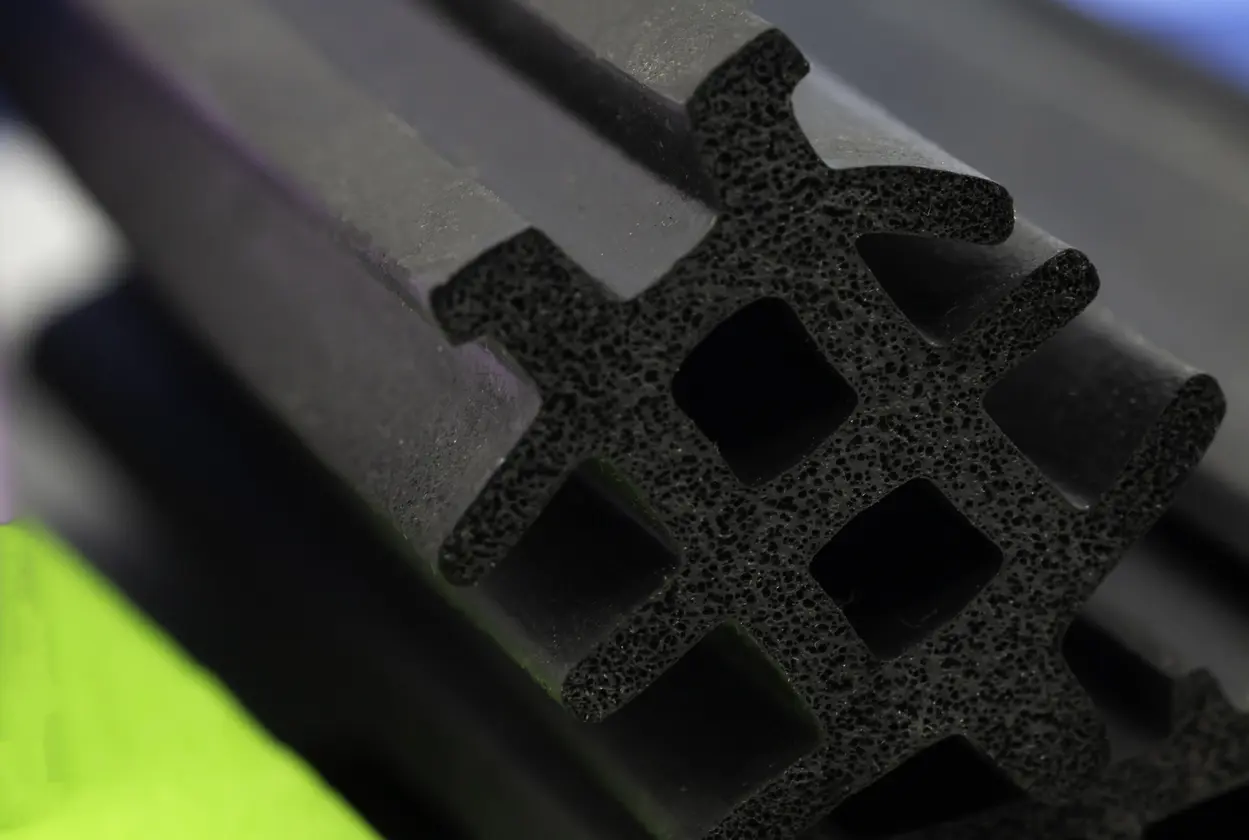

Sponge/Foam Molding

Does your part need extra strength without added weight? Sponge and foam injection molding offers the perfect balance. Our process uses a specialized blowing agent to form a tough, seamless outer skin around a lightweight foamed core. This method reduces part weight by up to 15%, which can improve handling, enhance efficiency, and cut material costs. Learn more about how Moldtech can support your needs below, or reach out to our team for a quote.

Why Trust Moldtech for Sponge and Foam Injection Molding?

Moldtech is known in the industry for solving complex engineering challenges. For decades, we’ve been a go-to partner for critical applications. When you need an expert to assist with your foam injection molding needs, turn to us.

Operating out of nearly 50,000 square feet of vertically integrated production space in Lancaster, NY, we manage every step of the manufacturing process. We’ll handle everything from the initial design to the final arrival at your facility. This means you get unmatched quality control on all your products. Our facility runs 24 hours a day, five days a week, enabling us to respond quickly to urgent requests. Whether that’s a single prototype or large production run, we’ve got you covered. And if your project requires additional safeguards, we offer cleanroom and climate-controlled environments.

Backed by decades of experience and the resources of Newbury Franklin Industrials, we’re ready to take on even the most challenging projects. In fact, we’re trusted by organizations like Boeing, Bosch, Johnson & Johnson, and the U.S. military. If you need high-quality parts that stand up to tough environments, trust us.

Get a Quote Today

Ready to learn more about what we can do for you? Our team is ready to get the details of your project and create a detailed quote. Contact us today to get started.